28++ Shell moulding process animation information

Home » Background » 28++ Shell moulding process animation informationYour Shell moulding process animation images are ready in this website. Shell moulding process animation are a topic that is being searched for and liked by netizens now. You can Get the Shell moulding process animation files here. Download all royalty-free vectors.

If you’re searching for shell moulding process animation images information related to the shell moulding process animation keyword, you have come to the right site. Our site frequently gives you hints for refferencing the maximum quality video and picture content, please kindly hunt and find more enlightening video articles and images that match your interests.

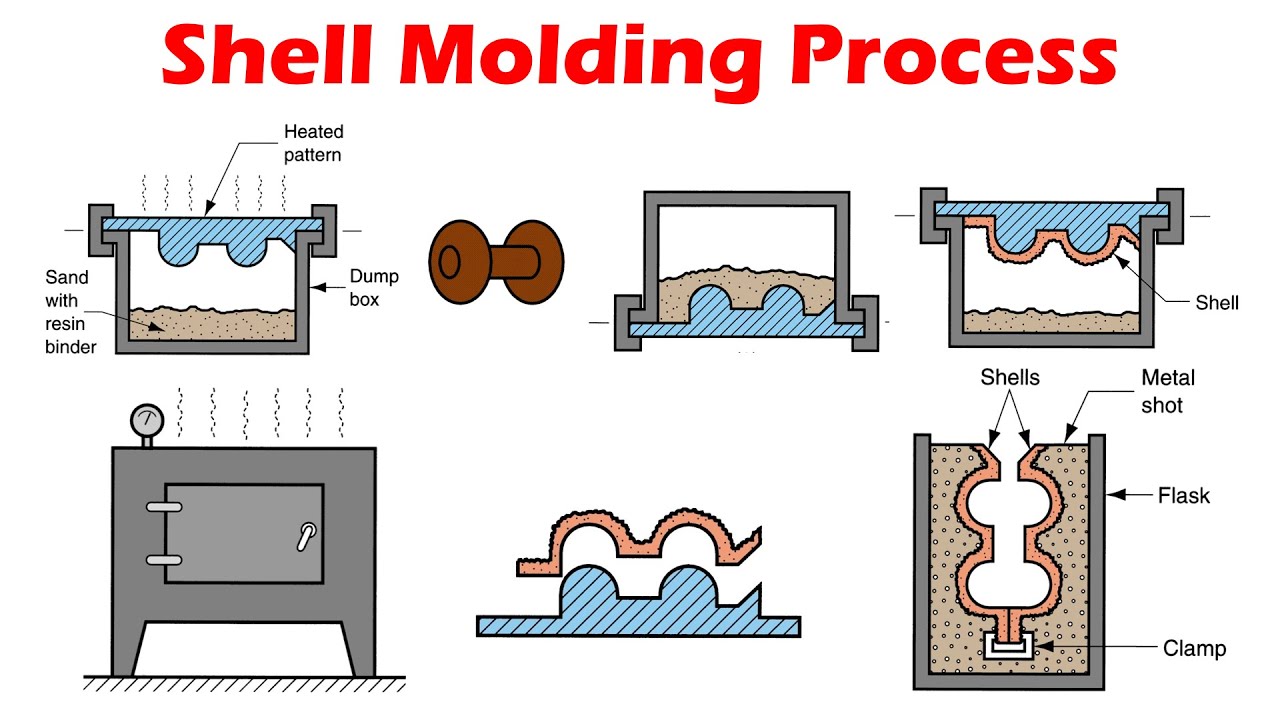

Shell Moulding Process Animation. Before shell casting can begin the shell mold must be created first. Shell moulding is an expendable process in nature which utilises resin covered sand to form the mould. Since 1946 we have been providing our customers the highest quality castings in a variety of metals all with an excellent surface finish and near-net shape. This process gives high accuracy and better surface finish.

Shell Molding Expandable Mold Casting Processes Shell Moulding Special Casting Process Youtube From youtube.com

Shell Molding Expandable Mold Casting Processes Shell Moulding Special Casting Process Youtube From youtube.com

Although it sounds complex shell mold casting is a relatively. One of the major advantages of this casting process which make it suitable for various casting industries is that it can easily automated. Its an animated example of casting a water mixer body by shell molding process I hope its useful to you. Mould creation - First each pattern half is heated to 175-370 C 350-700 F and coated with a. It is used for tiny to medium components that require high precision. The Shell Moulding Process.

One of the major advantages of this casting process which make it suitable for various casting industries is that it can easily automated.

HttpsyoutubeOtG-ox3i0kQFor more information about the shell molding process download our free Shell Moldi. Shell moulding is the preferred tool of the trade where high. Mould creation - First each pattern half is heated to 175-370 C 350-700 F and coated with a. As compared to sand casting this process has better dimensional accuracy a higher productivity rate and lower labor requirements. Its an animated example of casting a water mixer body by shell molding process I hope its useful to you. While the shell molding process allows foundries to produce intricate parts there are some cases when multiple pieces will be cast and welded together.

Source: youtube.com

Source: youtube.com

This method has greater dimensional precision a greater rate of productivity and reduced employment costs relative to sand casting. The Shell Mold Process Hiler Industries boasts two modern foundries that produce millions of castings every year all using the shell mold process. It is used for small to medium parts that require high precision. Shell moulding is an expendable process in nature which utilises resin covered sand to form the mould. Before shell casting can begin the shell mold must be created first.

Source: pinterest.com

Source: pinterest.com

Shell moulding also known as shell-mold casting is a process of expendable mold casting using resin-covered sand to form the mold. The Shell Moulding Process. Its an animated example of casting a water mixer body by shell molding process I hope its useful to you. This process gives high accuracy and better surface finish. First a two-piece metal pattern typically made from iron is created in the shape of the desired part.

Source: youtube.com

Source: youtube.com

Shell Molding Advantages One benefit of the shell molding process compared with other metal casting techniques is that castings produced this way often require minimal finishing. Although it sounds complex shell mold casting is a relatively. Introduction Shell molding also known as shell-mold casting It is an expendable mold casting process that uses a resin covered sand to form the mold. Before shell casting can begin the shell mold must be created first. WATCH THE UPDATED VERSION OF THIS VIDEO HERE.

Source: pinterest.com

Source: pinterest.com

The Shell Moulding Process. This process gives high accuracy and better surface finish. When the sand is poured into the heated mold it fills the. Mould creation - First each pattern half is heated to 175-370 C 350-700 F and coated with a. This method has greater dimensional precision a greater rate of productivity and reduced employment costs relative to sand casting.

Source: pinterest.com

Source: pinterest.com

Mould creation - First each pattern half is heated to 175-370 C 350-700 F and coated with a. This method has greater dimensional precision a greater rate of productivity and reduced employment costs relative to sand casting. While the shell molding process allows foundries to produce intricate parts there are some cases when multiple pieces will be cast and welded together. Shell molding process 1. The 6-Step Process of Shell Mold Casting.

Source: pinterest.com

Source: pinterest.com

First a two-piece metal pattern typically made from iron is created in the shape of the desired part. Shell moulding also known as shell-mould casting is an expendable mold casting process that uses a resin covered sand to form the mold. It is used for tiny to medium components that require high precision. Shell molding is a molding process invented by German engineer Johannes Croning in the mid-1900s. Shell moulding also known as shell-mold casting is a process of expendable mold casting using resin-covered sand to form the mold.

Source: youtube.com

Source: youtube.com

When the sand is poured into the heated mold it fills the. It provides higher dimensional accuracy high productivity and is economical at the labour end also. Each half is inserted into the shell core machine and heated to 400 F. Recknagel To mark the 50th anniversary of the death of the inventor Johannes Croning The inventor and entrepreneur Johannes Carl Adolf Croning was born on May 22 1886 in Hamburg as the son of a tradesman. Shell moulding is an expendable process in nature which utilises resin covered sand to form the mould.

Source: youtube.com

Source: youtube.com

It is the preferred method for the manufacture of gear. Shell moulding which is sometimes known as shell mold casting is one of a most suitable casting process for complex and other thin sections. The 6-Step Process of Shell Mold Casting. While the shell molding process allows foundries to produce intricate parts there are some cases when multiple pieces will be cast and welded together. It is heavily used in the manufacture of components for automotive industry.

Source: pinterest.com

Source: pinterest.com

Also known simply as shell molding shell mold casting is a casting process that involves the use of resin-covered sand for the mold. A German Innovation U. The Shell Moulding Process. Shell moulding is the preferred tool of the trade where high. Since 1946 we have been providing our customers the highest quality castings in a variety of metals all with an excellent surface finish and near-net shape.

Source: pinterest.com

Source: pinterest.com

Also known simply as shell molding shell mold casting is a casting process that involves the use of resin-covered sand for the mold. A German Innovation U. Like other molding processes it relies on a mold to create a new object often of a base material. Also known simply as shell molding shell mold casting is a casting process that involves the use of resin-covered sand for the mold. It is used for small to medium parts that require high precision.

Source: br.pinterest.com

Source: br.pinterest.com

It is used for small to medium parts that require high precision. Since 1946 we have been providing our customers the highest quality castings in a variety of metals all with an excellent surface finish and near-net shape. Shell moulding which is sometimes known as shell mold casting is one of a most suitable casting process for complex and other thin sections. One of the major advantages of this casting process which make it suitable for various casting industries is that it can easily automated. Each half is inserted into the shell core machine and heated to 400 F.

Source: pinterest.com

Source: pinterest.com

PROCESS Shell Moulding involves the following processes Pattern creation - A two-piece metal pattern is created in the shape of the desired part typically from iron or steel. Before shell casting can begin the shell mold must be created first. Shell mold casting is a metal casting process similar to sand casting in that molten metal is poured into. Shell molding is a molding process invented by German engineer Johannes Croning in the mid-1900s. It provides higher dimensional accuracy high productivity and is economical at the labour end also.

Source: youtube.com

Source: youtube.com

WATCH THE UPDATED VERSION OF THIS VIDEO HERE. One of the major advantages of this casting process which make it suitable for various casting industries is that it can easily automated. Molten metal is poured into the molds cavity at which point the mold vaporizes to create a hard shell. Shell molding is a molding process invented by German engineer Johannes Croning in the mid-1900s. Since 1946 we have been providing our customers the highest quality castings in a variety of metals all with an excellent surface finish and near-net shape.

Source: pinterest.com

Source: pinterest.com

As compared to sand casting this process has better dimensional accuracy a higher productivity rate and lower labor requirements. The 6-Step Process of Shell Mold Casting. Prepared by Paija Jigesh Dhameliya Bhavesh 2. Shell molding is a molding process invented by German engineer Johannes Croning in the mid-1900s. Shell mold casting is a metal casting process similar to sand casting in that molten metal is poured into.

Source: pinterest.com

Source: pinterest.com

Shell molding process 1. This method has greater dimensional precision a greater rate of productivity and reduced employment costs relative to sand casting. Its an animated example of casting a water mixer body by shell molding process I hope its useful to you. Shell molding is unique however because it uses resin-covered sand as a base material. Application of shell moulding-.

Source: youtube.com

Source: youtube.com

Before shell casting can begin the shell mold must be created first. WATCH THE UPDATED VERSION OF THIS VIDEO HERE. Shell moulding is the preferred tool of the trade where high. It is used for small to medium parts that require high precision. Mould creation - First each pattern half is heated to 175-370 C 350-700 F and coated with a.

Source: youtube.com

Source: youtube.com

STEP 1 THE SHELL MOLDING PROCESS. Prepared by Paija Jigesh Dhameliya Bhavesh 2. Recknagel To mark the 50th anniversary of the death of the inventor Johannes Croning The inventor and entrepreneur Johannes Carl Adolf Croning was born on May 22 1886 in Hamburg as the son of a tradesman. Its an animated example of casting a water mixer body by shell molding process I hope its useful to you. Introduction Shell molding also known as shell-mold casting It is an expendable mold casting process that uses a resin covered sand to form the mold.

Source: pinterest.com

Source: pinterest.com

STEP 1 THE SHELL MOLDING PROCESS. The Shell Mold Process Hiler Industries boasts two modern foundries that produce millions of castings every year all using the shell mold process. The 6-Step Process of Shell Mold Casting. It is the preferred method for the manufacture of gear. Shell molding process 1.

This site is an open community for users to share their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site value, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title shell moulding process animation by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.

Category

Related By Category

- 32++ Janes animal expedition ideas in 2021

- 10++ Miserable animals ideas in 2021

- 45+ Pyoderma in animals information

- 40++ Shiba anime info

- 48+ Madam rides the bus animation information

- 31++ Rotary piston engine animation ideas in 2021

- 41++ Ming dynasty animals information

- 22+ Kyoto animation recovery ideas in 2021

- 44++ Neuroscience animation ideas in 2021

- 47++ Ratel honey badger animal ideas in 2021